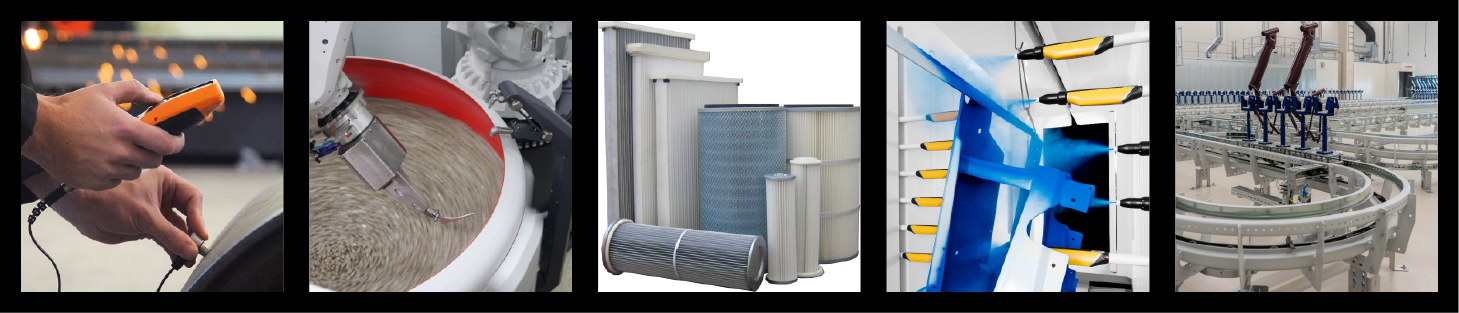

Tailored inspection plan for quality control of rack plating

place with metal hooks or bands, before being submersed

in the plating solution where the electrical current is applied. However, narrow tolerance limits and strong demand for homogeneous coatings require precise measurements of the coating thickness according to clearly defined testing procedures. In addition, the measurement results should provide clues for potential process optimisation and even cost reduction.

Electroplated coatings must fulfil various criteria, for example, functional coatings must provide a certain level of corrosion protection. This requires at least a minimum plating thickness without adding unnecessary costly layers. The coating should also be as homogeneous as possible, not only within a given rack, but from rack to rack; this is important for both functional and decorative coatings. Another consideration is that coating processes often need to be executed within narrow tolerance limits. To check all these criteria systematically, test measurements should always be taken in the same spots, in the same way, regardless of who is currently executing the inspection. Furthermore, a number of workpieces must be tested, and that with as little effort as possible.

An effective way of controlling is to use individual inspection plans. For this purpose, Fischer has developed its DataCentre IP (inspection plan) software, which, utilised in combination with the DUALSCOPE® FMP100 coating thickness measurement instrument, allows a user to define inspection plans on the PC and download them onto the FMP100.

The inspection plans guide an operator step-by-step, like

a navigation system, through complex measurement tasks, providing exact instructions enhanced by images and text. The measurement spots are thus distributed evenly throughout the rack and set so that they capture all the critical areas (like edges). Via the pre-defined inspection plan, all measurement spots can be unambiguously identified. At the same time, a number of customer and process-associated data can be taken and later transferred into a fully customisable report.

The readings are then downloaded directly to the PC for

easy evaluation, archiving and printing (with configurable templates). For this purpose a wide variety of analysis and statistic functions, as well as supporting graphical displays,

are available.

To summarise, Fischer’s DataCentre IP software and DUALSCOPE® FMP100 handheld instruments put the powerful tools of strategic quality control directly into inspectors’ hands. Step-by-step guidance through the complete measurement cycle not only minimises human error, ensuring reproducible and comparable results on defined measurement spots, but qualifies these instruments for use even by non-technical operators. Structured measurement recording and extensive evaluation options further help to identify potential improvements in production processes.

Telephone: 01590 684100

Email: ccave@fischergb.co.uk

Visit: www.fischergb.co.uk